This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Steriliser and Autoclave Validation (Temperature Validation Equipment)

History tells us that regulations and compliance requirements are constantly evolving. This is especially true for the pharmaceutical and health industries as improved technologies and practices appear on the horizon.

In this guide we are addressing the choice of temperature calibration equipment available to enable the site calibration engineer to provide local maintenance for autoclaves and sterilisers, generally used but not exclusively by hospitals.

HTM Requirements

A previous incarnation of the regulatory requirement has been HTM2010 which details the testing parameters for sterilisers and autoclaves. This is currently being superseded by the HTM-01 series. It involves measurements of temperature and pressure along with the reporting of results to an agreed standard.

Here, we will specifically look at the options for temperature measurement and the appropriate equipment/accessories needed to provide accurate, stable and traceable temperature calibration results.

Relevant Requirements for temperature Calibration equipment:

“Thermometric tests use accurate measuring equipment to monitor temperatures and pressures independently of the instruments fitted to the steriliser. They provide the assurance that the temperature requirements for sterilisation are met”

“The calibration of all instruments should be verified yearly by using reference instruments with a valid certificate of calibration traceable to a national standard”

“An independent temperature reference source (a hot source) is required, with a pocket to accommodate up to 12 temperature sensors. The temperature gradient should not exceed 0.2°C and the control accuracy should be within ±0.1°C over the relevant sterilisation temperature band.”

Click the links to move to the relevant area of your interest:

OPTION 1: Fast-Cal Low Complete

Comprises of Hot Source dry-well and built-in PRT reference probe, with UKAS (ISO 17025) calibration certificate available. This is the most popular choice with health professionals. Is small and portable and comes supplied with a canvas shoulder bag which holds extra probes and insert pockets.

- Temperature Range -35°C to +140°C

- Stability ±0.02°C

- Accuracy ±0.15°C

OPTION 2: Fast-Cal Low Basic + High Accuracy Handheld Thermometer /Probe 935-14-61

Comprises of a stable Hot Source Dry-Well and separate Measurement System. The thermometer/probe system is a high accuracy indicator capable of circa 20mK measurements.

- Stability ±0.02°C for the Hot Source

- Accuracy ±0.02°C for Handheld Thermometer/Probe system

Options for Pockets

With our on-site Engineering Services, Isotech can also manufacture your “pockets” for the sensors that are specific to your site/equipment and your on-site temperature calibration needs. We acknowledge that all sensors are different sizes and dimensions and getting the correct immersion in the hot-source is vital for good measurement.

OPTION 3: Portable Liquid Baths

Gaining popularity in recent years is the use of wireless dataloggers that are placed in the sterilisation chambers during a program. These need to be validated but do not lend themselves to a traditional dry hot source. Isotech can also provide a portable liquid bath solution.

- Portable Liquid Bath : Hyperion Site (-25°C to +140°C), Drago Site (+30°C to +250°C)

Comprises of Hot Source Liquid Bath and a built-in reference probe, UKAS calibration certificate available.

| Hyperion | Drago | |

| Stability | From +/- 0.03°C | |

| Uniformity (Radial) | <0.009°C | <0.007°C |

| Uniformity (Axial) | <0.011°C | <0.013°C |

Note:These models have the added advantage that the liquid insert can be removed and the unit can be used as a dry-well, surface sensor calibrator, blackbody target and also as a ITS-90 Fixed Point cell.

OPTION 4: Portable Liquid Bath with High Accuracy Bench Thermometer/Probe 935-14-61

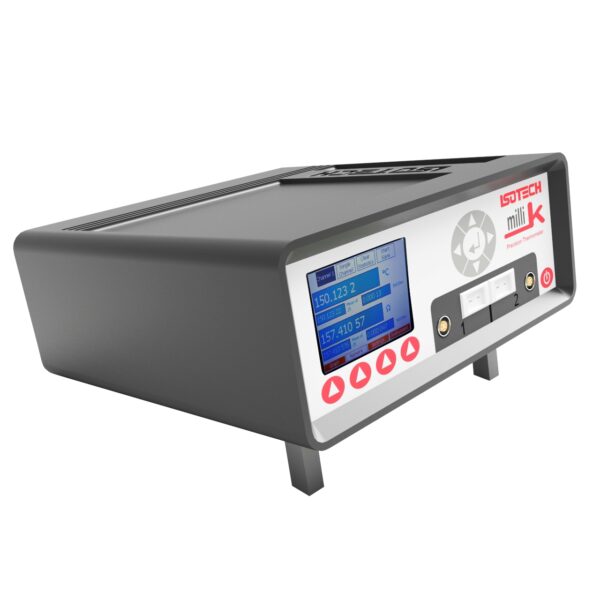

Portable Liquid Bath : Hyperion Basic (-25°C to +140°C), Drago Basic (+30°C to +250°C) with separate milliK Precision Thermometer and Reference Probe.

Note: The milliK Precsion Thermometer can log data and “drive” the hot source through a user specified temperature program

Fully Traceable Temperature Calibration (UKAS)

The products above can be supplied with a calibration performed in our laboratory that is accredited to ISO 17025 and are ideal for on-site temperature calibration. Typically, we would provide a five point temperature calibration for a hot source with the reference built in. For the separate Handheld Thermometer/probe system our calibration engineers would provide a lower uncertainty “curve fit” to characterise the PRT and it’s response to temperature changes, we would then generate co-efficients and program these into the unit for you. A UKAS Certificate will be issued in each case.

The regulated industries such as Pharmacuetical, Food & Beverage and Healthcare routinely use climatic storage facilities for their products

These storage “chambers” will typically hold products where it is important to accurately control and monitor their physical state, e.g Blood Storage, Frozen Foods, Medicines. This will generally contribute towards optimisation of the product shelf life.

The chambers are usually benchtop or floor standing devices, although larger, walk-in chambers can also be found for large scale storage. Also, humidity measurements generally go hand in hand with temperature measurements.

It follows then that the chambers will need to be validated as fit for purpose and will need to comply with often strict regulations/good practices issued by bodies such as FDA, CFR, ICH, UKAS, etc. Related is in the aerospace industry, chamber mapping / temperature uniformity surveys (TUS) to ASTM 2750F.

Here we show two common configurations widely used by most calibration engineers and illustrate the equipment needed for validating the chamber temperature.

OPTION 1: Dataloggers Between Use

Dataloggers are supplied in a variety of designs from small “coin” shaped design to credit card sized devices. These loggers will need to be calibrated. There are various ways this can be performed but we recommend a first principles approach.

Using the Zeroth Law of Thermodynamics – we will immerse these loggers in a liquid medium alongside a UKAS calibrated, traceable reference probe and perform a Comparison Calibration.

This can be carried out with the Hyperion “wide aperture (65mm)” temperature calibrator. The dataloggers are lowered into the liquid, the temperature of which is accurately controlled with a high accuracy PID controller.

Option 2: Realtime Monitoring

Increasingly, we are being asked for a solution for “monitoring” the chamber with more accurate sensors and in real time.

In this scenario a common approach is to have multiple certified sensors inserted through the wall of the chamber. These sensors can be routed directly to a precision thermometer and their data collected for later reporting.

For this method, Isotech offers the milliK Precision Thermometer with millisKanner expansion unit – providing capability of up to 32 sensors with increased accuracy.

These sensors can be PRTs or Thermocouples (for higher temperatures). Isotech can also supply the appropriate sensor for your temperature range.

Temperature switches are used in many applications, from ovens for the catering industry and domestic thermostats in the home to chemical processes and air conditioning in hotel rooms.

A Thermostat will have a temperature sensor which is programmed to make a change at a given temperature. Here we will show the equipment required to accurately test this function and provide a calibration.

Principle of Calibration

A temperature switch is an electrical contact that completes a circuit when activated. This circuit can prompt a response in the system such as initiating a cooling device if the sensor gets too hot, or sending an alarm signal to a control panel if a defined process temperature is reached.

The electrical contact in the switch will generally be in one of two states, “normally open” or “normally closed”, and will switch to the other state when activated.

To test this switch point, we need to slowly ramp the temperature past the activation point to determine the temperature of activation. How do we do this?

Equipment

Here at Isotech, we assist our customers in choosing the most appropriate equipment to control this ramp. For a typical catering oven, a dry-well temperature calibrator is a recommended.

The dry-well will hold the temperature sensor under test, and alongside it will also hold a UKAS certified reference probe. The system is then programmed with a temperature ramp to take the sensor through its activation range.

It is obvious that if the ramp happens too fast, we can overshoot the switch point and the recorded temperature of switching may not be accurate. This is why Isotech use world leaading PID control on our dry-wells. Not only can the user adjust the control ramp rate to 0.01°C per minute, but we can also tell the controller if the sensor under test is normally open or normally closed at the start of the ramp. When the switch point is reached the display will “freeze”, very handy if the calibration engineer is multitasking and isn’t sat next to the drywell at the time.

In addition, our customers will routinely test this switch point activation by both ramping up and also ramping down.

Often, the site engineer is called upon to calibrate sensors that are monitoring high temperatures. Pyrometry and Infrared Imaging devices can offer a safe check from outside the hot environment but how do we “replicate” the temperature conditions that the monitoring sensor is actually being subjected to during normal use?

Isotech have a solution for this.

The Pegasus portable furnace temperature calibrator for temperatures up to 1200°C, perfect for on-site temperature calibration.

As with our lower temperature dry-blocks, the Pegasus Portable Furnace is available in 3 designs, Basic, Site and Advanced.

We recommend the Site or Advanced models with built-in Reference probe (typically a Type R Thermocouple) for on-site temperature calibration. These models can be supplied with a UKAS calibration certificate issued by one of our Accredited Laboratories.

Heating and Cooling Times

Isotech recognises the typical site engineer’s day can mean waiting for temperature points to be reached before measurements can be taken, and also when the job is finished the furnace needs to be cooled to a safe temperature before the equipment is packed for departure from site.

Isotech have a solution to make life easier in this situation.

The typical cooling times below can be substantially reduced by using the cooling adapter (requires source of instrument air).

We are here to help you

Making sure you get the product you need