This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Addressing Inhomogeneity Of Thermocouples

Thermocouples are the most used, and most calibrated of temperature sensors. Thermocouples offer many advantages but also have some disadvantages and are often misunderstood.

With a thermocouple there is nothing ‘magic’ about the junction, the junction is not the temperature sensor and the thermocouple voltage is not generated at the junction.

Thermocouples rely on the Seebeck effect which states that when heat flows in a conductor, an emf is generated. So, with a thermocouple, the whole length of the wire matters, and the voltage will be generated in the part of the wire where the temperature gradient is and not the junction.

If a thermocouple wire has a consistent material throughout the whole length and also the same chemical properties, we can say that it is homogeneous, although in practice thermocouples are not homogeneous and errors arise from inhomogeneities.

“Guidelines on the Calibration of Thermocouples EURAMET Calibration Guide No. 8 Version 3.” has new information about “the effect of inhomogeneity on the uncertainty” and states, “Inhomogeneity can be quantified by moving the measuring junction in an environment with homogenous temperature distribution (e.g. a stirred liquid bath or a fixed point cell, or specialised single gradient scanner”

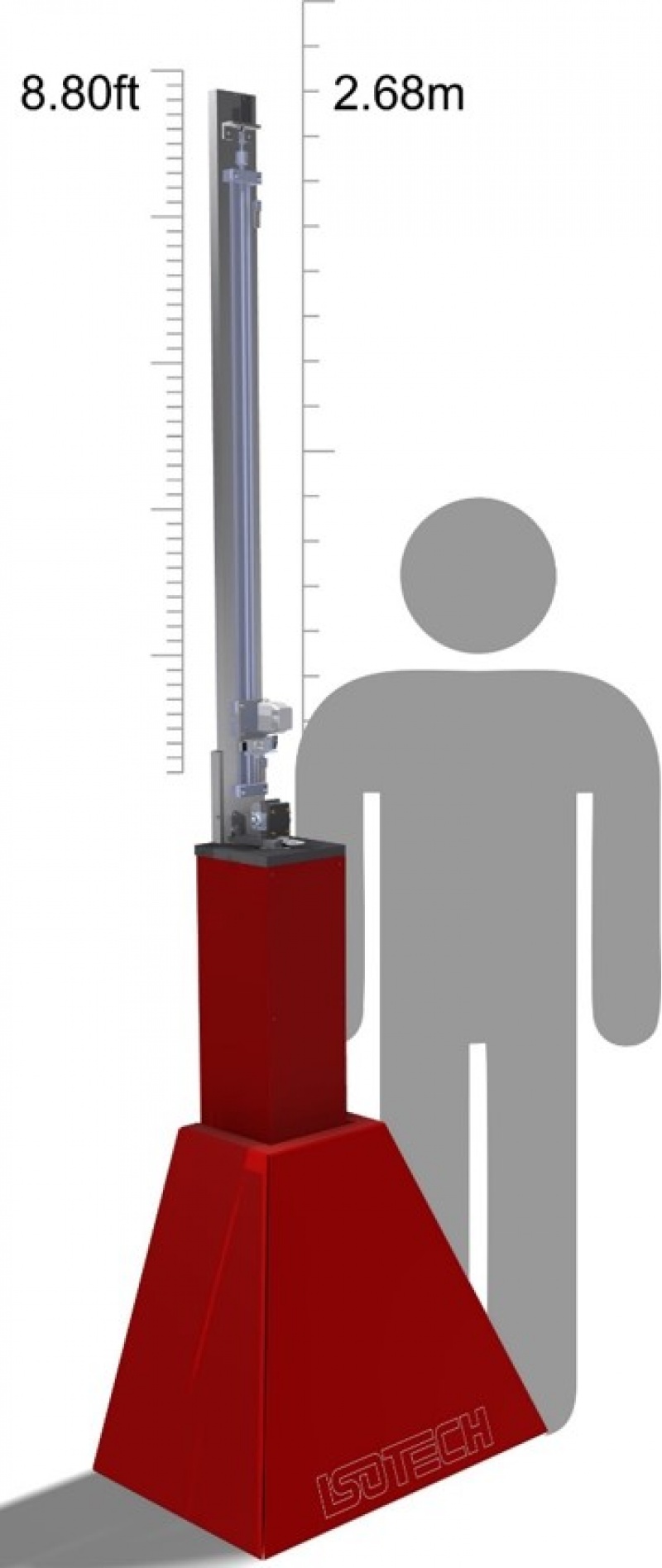

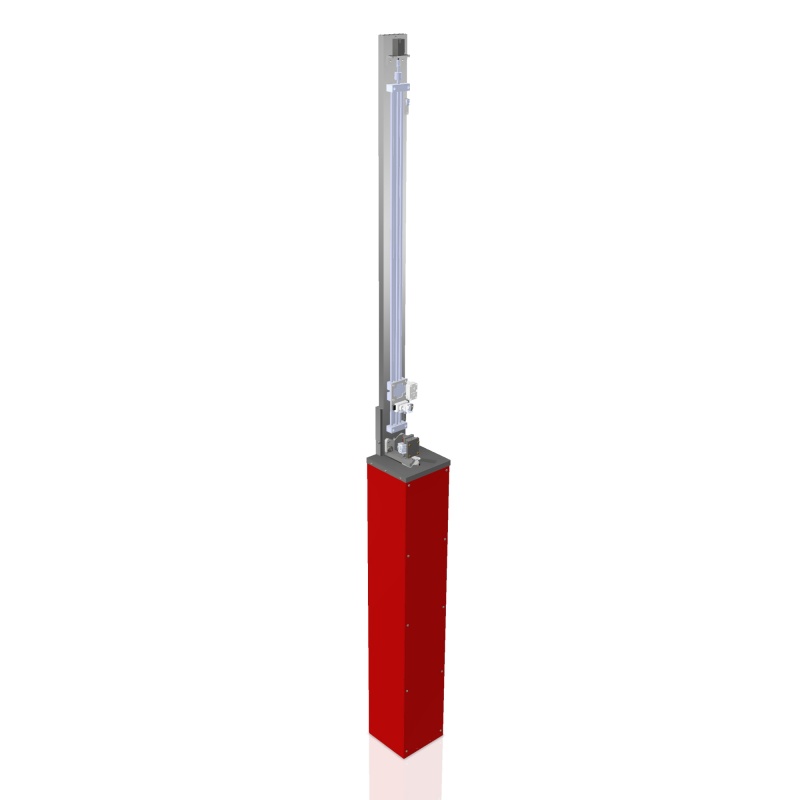

Isotech Model 881 Thermocouple Scanner

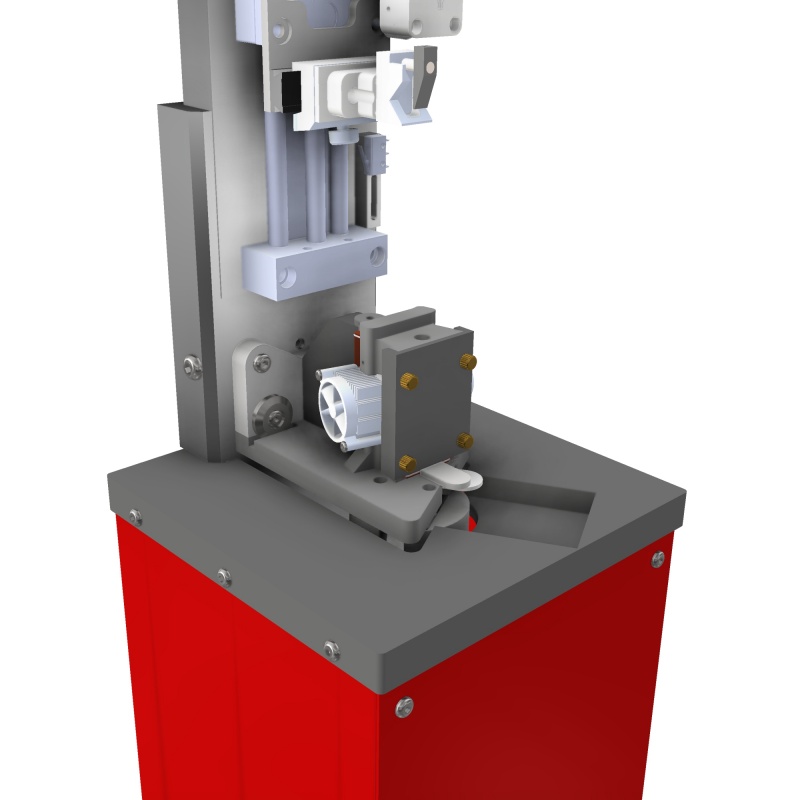

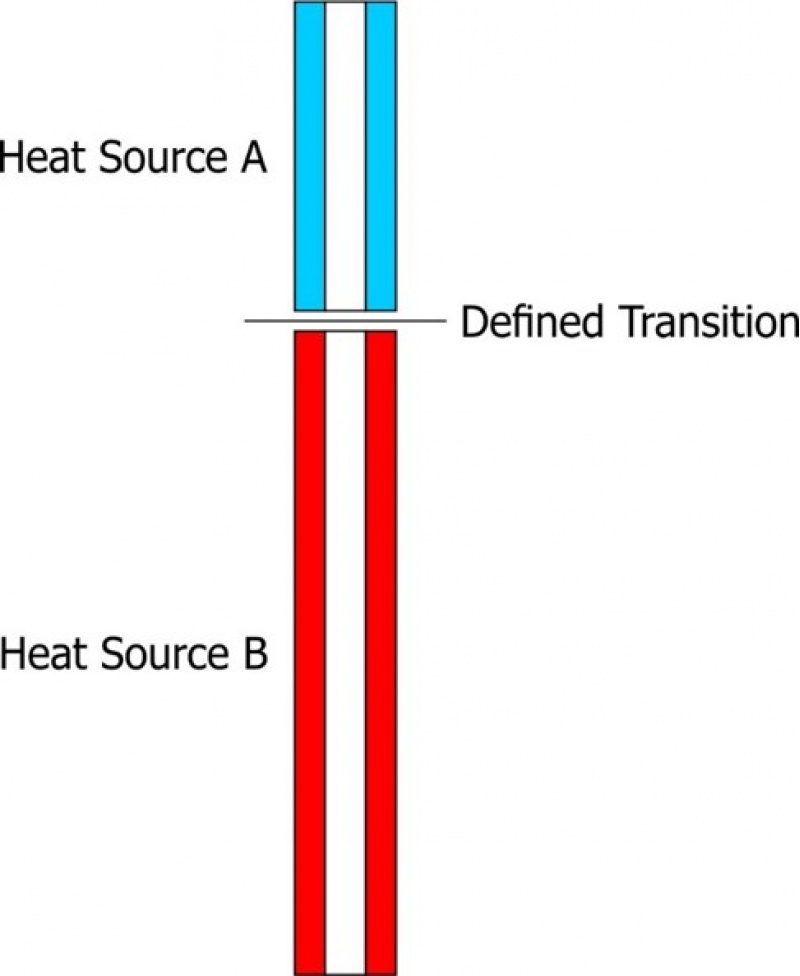

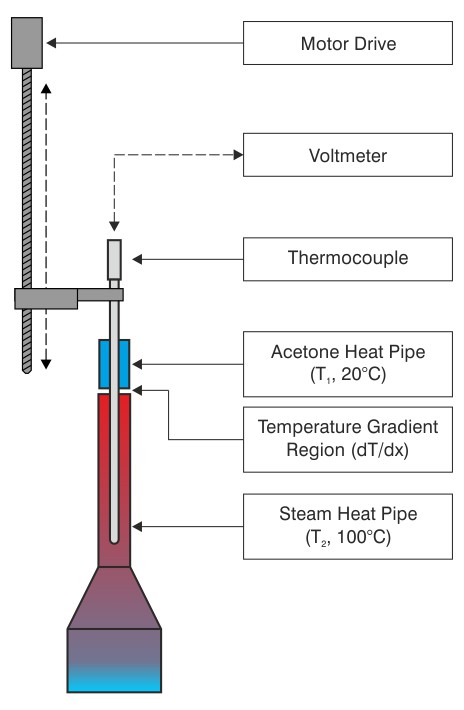

Model 881 provides an automated solution to scan thermocouples to identify uncertainty due to inhomogeneity. The scanner uses two heat-pipes at two different temperatures to provide a compressed knife-edge temperature gradient. The test thermocouples are raised through this gradient while the software automatically controls a linear actuator and records the voltage from a digital voltmeter. At the end of the test, the uncertainty is calculated.

Benefits of the Thermocouple Homogeneity Scanner

Determine Thermocouple Performance

Identify thermocouple performance to allow uncertainty to be calculated rather than guessed (Type A uncertainties). Most thermocouple uncertainty budgets currently rely on indicative type B assessments of inhomogeneity. Inhomogeneity is normally the largest uncertainty component and therefore has the greatest effect on accuracy. By measuring the uncertainty of thermocouples with better performance, they can be assigned a lower uncertainty that reflects the measured performance with a three-fold improvement on accuracy being possible.

It also allows thermocouple submitted for calibration to be assessed and to determine if they are worth calibrating.

Determining performance allows for confidence in thermocouple standards across the length of the thermocouple perhaps identifying parts of the thermocouple that should be avoided. A further benefit is to know if a thermocouple needs annealing and also post-annealing if the process has been successful.

When Manufacturing or Selecting Thermocouples

Thermocouple homogeneity scanning allows the quality of the wire over its length to determined, thus allowing for the determination of the quality of the thermocouple wire. It allows identification of variations in different production batches and also of one manufacturer of wire to be compared to another. It offers a new way to identify failures and defects in batches of thermocouples.

Features of the Thermocouple Homogeneity Scanner

- Utilises a unique dual heat-pipe arrangement

- This arrangement produces the essential knife-edge single gradient developed from research

- Scanning times reduced to less than 20 minutes

- Fast efficient scanning with fully automated motion and logging

- Scanning resolutions of between 2 mm and 5 mm

More Than 10 Years in Development

Developed at MSL in New Zealand the design has undergone several developments since the first single water heatpipe from 2008. The design is now exclusively licensed to Isotech

Compared to a scanner at NPL, UK

NPL in the UK have recently and found our commercial device is consistent with a different type of non-commercial scanner in use at the NPL

NPL Report on the Isotech Homogeneity Scanner

Based on World Leading Research

- Greenen, A. and Webster, E. S. “Thermal recovery From cold-working in Type K bare wire thermocouples.” Int. J. Thermophys 38 (2017): 1-13.

- Webster, E. “The Type N Thermocouple: The Good, the Bad and the Ugly.” Paper presented at the meeting of the Proc. MSA Conference Australasia, 2017.

- Webster, E. S. “Seebeck Changes Due to Residual Cold-Work and Reversible Effects in Type K Bare-Wire Thermocouples.” Int. J. Thermophys. 38 (2017): 1-18.

- Webster, E. S. “Drift in Type K Bare-wire Thermocouples from Different Manufacturers.” Int. J. Thermophys. 38 (2017): 1-14.

- Webster, E. S. “Thermal Preconditioning of MIMS Type K Thermocouples to Reduce Drift.” Int. J. Thermophys. 38 (2016): 1-14.

- Webster, E. S. “Effect of annealing procedure in determining drift as a function of temperature between 170°C and 900°C in Type S thermocouples.” Int. J. Thermophys. 36 (2015): 1909-1924.

- Webster, E. S. “Low-temperature drift in MIMS base-metal thermocouples.” Int. J. Thermophys. 35 (2014): 574-595.

- Webster, E. S. and Edler, F. “Drift as a function of temperature in platinum-rhodium-alloyed thermoelements.” Int. J. Thermophys. 38 (2016): 1-14.

- Webster, E. S. and White, D. R. “Thermocouple homogeneity scanning.” Metrologia 52 (2015): 130-144.

- Webster, E. S., White, D. R. and Edgar, H. “Measurement of inhomogeneities in MIMS thermocouples using a linear-gradient furnace and dual heat-pipe scanner.” Int. J. Thermophys. 36 (2014): 444-466.

- White, D. R. and Mason, R. S. “A Thermocouple Homogeneity Scanner Based On An Open Pressure-controlled Water Heatpipe.” Int. J. Thermophys. 31 (2010): 1654-1662.

We are here to help you

Making sure you get the product you need