This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

One area where greater accuracy is crucial is environmental control systems in buildings. Historically, an accuracy of around 1°C may have sufficed however improving measurements to within a few hundredths of a degree can save tens of thousands of pounds and is possible using high-accuracy traceable solutions.

Accurate temperature measurements require suitable sensors and measuring instruments. For high-precision measurements from around -200°C to 660°C, Platinum Resistance Thermometers (PRTs) offer many advantages. At higher temperatures, Noble Metal Thermocouples outperform lower-cost base metal alternatives.

Platinum Resistance Thermometers (PRTs) and Thermocouples

The IEC 60751:2022 standard, “Industrial platinum resistance thermometers and platinum temperature sensors,” defines tolerances for industrial PRTs, with the tightest being 0.1°C at 0°C rising to 0.53°C at 250°C. PRTs operate on the principle that platinum’s electrical resistance changes predictably with temperature, making them ideal for precise measurements.

While a 0.1°C to 0.5°C tolerance is good, many applications demand even greater precision.

By individually calibrating a PRT’s coefficient to characterise its resistance-temperature curve, its temperature can be uniquely calibrated rather than using IEC 60751 table values. This can improve measurement accuracy by a factor of 10.

Thermocouples

Thermocouples work on a different principle: the Seebeck effect. When two dissimilar metals are connected with their junctions at different temperatures, a small voltage is generated. Noble metal thermocouples can perform well at high temperatures and can be calibrated by producing an error curve to correct them against IEC 60584-1:2013.

Measuring Instruments

While a high-precision digital multimeter (DMM) could measure PRT resistance or thermocouple voltage, a dedicated thermometer offers more advantages. Good thermometer designs allow entering calibration coefficients for the PRT or thermocouple, enabling direct display of the corrected temperature.

Benefit from Isotech PRTs and Thermocouples

Drawing from four decades of industry-leading expertise, our Platinum Resistance Thermometers (PRTs) incorporate hand crafted, high-stability platinum coils, facilitating an extensive temperature range, exceptional accuracy, and minimal drift. Post-assembly, these PRTs undergo a rigorous process of annealing, proprietary thermal treatments, and multi-cycle stability testing, ensuring industry leading accuracy. Our thermocouples are engineered with the finest available metal alloys and like the PRTs, undergo a proprietary post-production process, delivering outstanding performance.

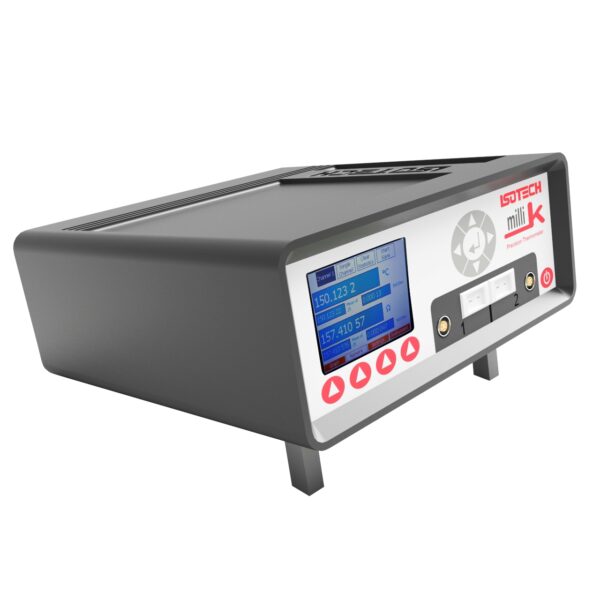

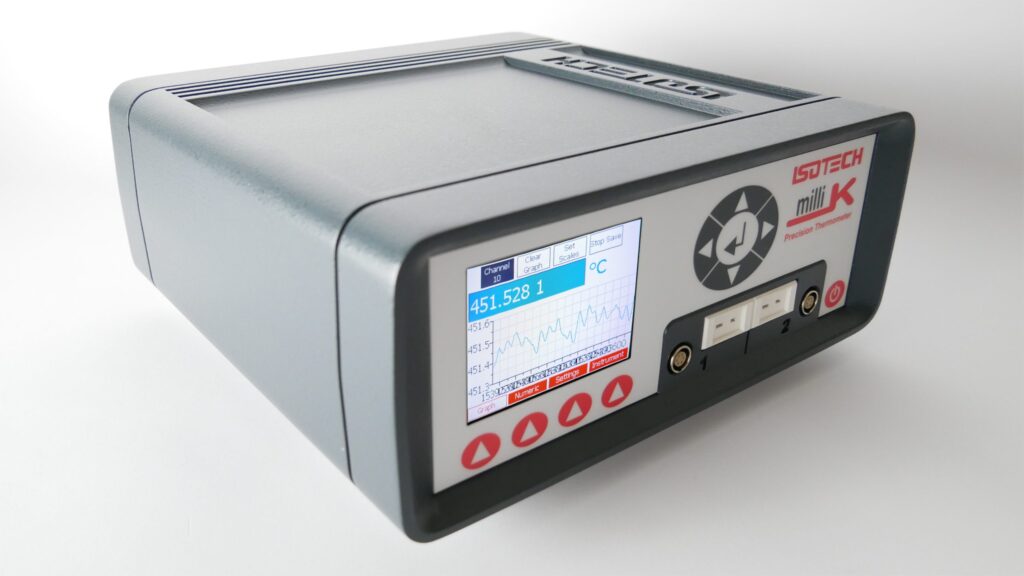

Isotech milliK Precision Thermometer

The milliK precision thermometer boasts industry-leading accuracy for PRTs and thermocouples. It also supports current transmitters and thermistors. The milliK can store probe correction coefficients and features a colour numeric display and built-in logger for easy use.

Calibration

To achieve higher accuracy, sensors must be precisely calibrated, with the option to use calibration results to correct errors. Correct calibration also provides traceability. The instrument can be supplied with UKAS (United Kingdom Accreditation Service) ISO 17025 calibration from our leading in-house laboratory.

Dry Blocks and Calibration Baths

The milliK, when paired with a heat source, enables calibration of industrial sensors across an extensive temperature range of -200°C to 1300°C. Our comprehensive calibration solutions include a range of dry block calibrators and stirred liquid baths, accommodating probes of varying sizes – from compact portable devices to larger laboratory units. We offer portable models for on-site calibration as well as laboratory models, ensuring versatility and precision across for all types of temperature sensors.

Experience

Selecting correct high-accuracy traceable solutions for measurements and calibration is a critical decision that can significantly impact the efficiency and reliability of the calibration process.

With over 40 years of experience in designing, manufacturing, and operating a world-leading temperature calibration laboratory, we can guide you in choosing the most appropriate solutions for your specific needs. Take a look at consultancy options.